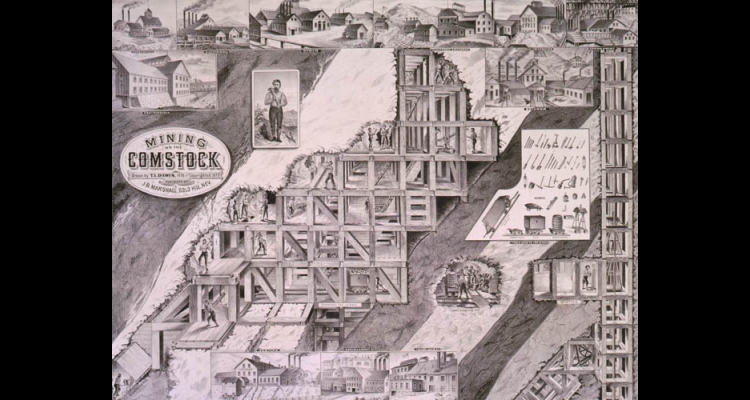

Square Set Timbering

Comstock mining began in 1859 with open pits at Gold Hill to the south and Virginia City to the north. Within months, the Ophir Mine pit at Virginia City's outcropping became perilously deep, forcing miners to excavate underground.

The Comstock challenged traditional methods of supporting mines with timbers assembled in an inverted "U." The decomposed quartz embracing the ore tended to fold itself around wooden supports, collapsing on excavations. In addition, the ore vein expanded up to sixty feet wide. A single timber supporting such a span would snap.

W. F. Babcock, a trustee of the Ophir Mine, asked Philipp Deidesheimer, a German born and trained engineer, to design a solution. By late 1860, he developed the famed square-set timber method, a modular approach that assembled prefabricated timbers into cubes. These were six to seven feet tall and four to six feet wide. With cubes stacked on cubes, they could support virtually any underground chasm. The system became stronger when filled with waste rock, which was more efficient than hauling debris to the surface.

Costs for lumber increased, but other mines quickly adopted the system. Deidesheimer's square-set timbers became an international standard in mining for the next fifty years.

Article Locations

Related Articles

None at this time.